The potential impact of a new sensing technology on the manufacturing sector in the United Kingdom cannot be understated. Researchers from the University of Bristol have made significant strides in developing a formula that could revolutionize the way in which the quality of components is assessed. This breakthrough has the potential to transform industries, particularly in the field of additive manufacturing (3D printing).

One of the key components of this innovation is the use of ultrasonic array sensors. While these sensors are not entirely new (as they are commonly used in medical imaging), the application of laser-based versions without the need for direct contact with the material is truly groundbreaking. Professor Anthony Mulholland, head of the School of Engineering Math and Technology, highlighted the potential of this technology in assessing the mechanical integrity of components.

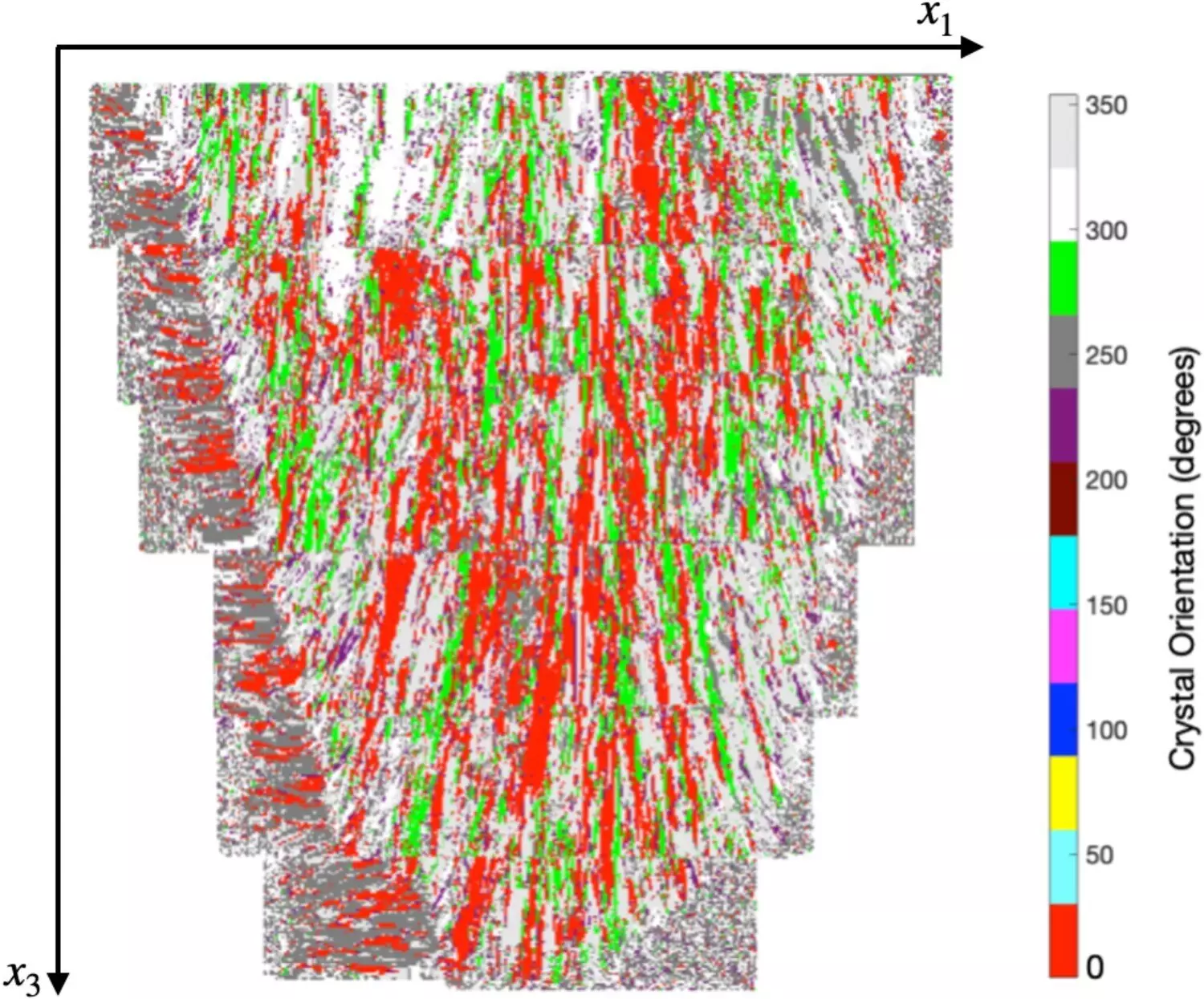

The research team at the University of Bristol has delved into mathematical modeling to better understand how ultrasonic waves propagate through layered metallic materials. By considering the variability between each manufactured component, they have developed a formula that incorporates design parameters related to the ultrasonic laser and the specific material being used. This mathematical model aims to maximize the information content produced by the sensor for accurate quality assessment.

The impact of this discovery on the manufacturing industry is immense. Professor Mulholland emphasized that the deployment of laser-based ultrasonic arrays in controlled additive manufacturing environments could lead to faster, more cost-effective production processes. This could potentially result in entirely new designs that take full advantage of 3D printing technology, ultimately providing a significant commercial and economic advantage to U.K. manufacturing.

Moving forward, the research team plans to collaborate with industry partners to implement this technology in practical manufacturing settings. By deploying laser-based ultrasonic arrays using robotic arms, they aim to maximize the information obtained from the sensors and generate tomographic images of component interiors. By utilizing destructive means to assess the quality of these images, the team hopes to validate the effectiveness of their innovative approach.

The ability to assess the mechanical integrity of safety critical components, particularly in industries such as aerospace, could open up a world of opportunities for U.K. manufacturing. The lack of effective quality assessment methods has been a major challenge in leveraging the full potential of 3D printing technology. However, with the advancements made by the University of Bristol researchers, this hurdle may soon be overcome.

The development of a sensing technology that can accurately assess the quality of components is poised to revolutionize the manufacturing sector in the United Kingdom. By leveraging ultrasonic array sensors and mathematical modeling, researchers are paving the way for faster, more efficient production processes and innovative design possibilities. The implications of this innovation extend far beyond the realm of academia, offering tangible benefits to industries and the economy as a whole.

Leave a Reply