The University of Illinois Urbana-Champaign has recently introduced a groundbreaking approach for detecting defects in additively manufactured components. This method aims to address the challenge of identifying flaws in components produced through additive manufacturing, which can be intricate and difficult to examine due to their complex three-dimensional shapes and concealed internal features.

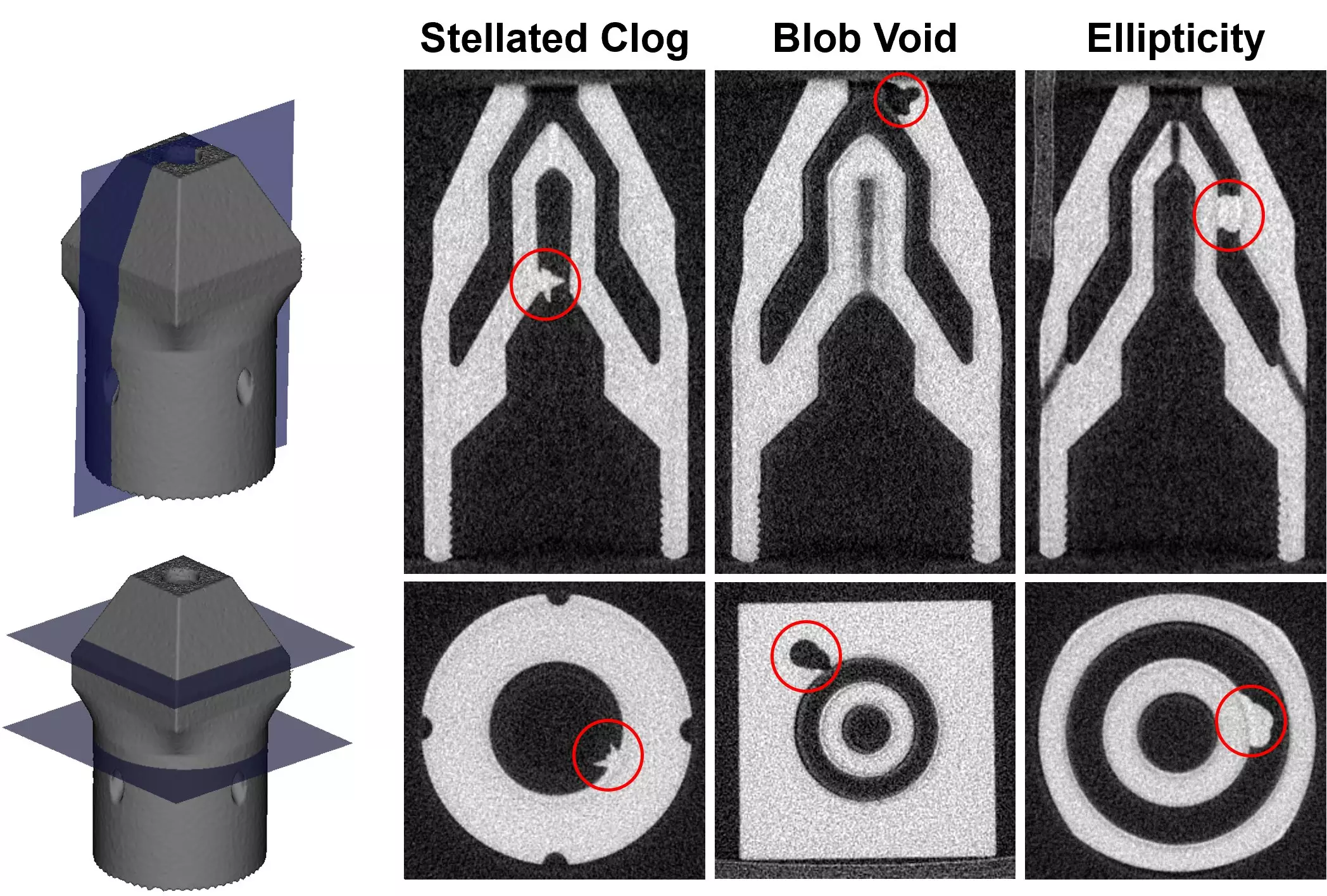

The innovative technology leverages deep machine learning to enhance the detection of defects in additively manufactured components. Through computer simulations, researchers generated numerous synthetic defects with varying sizes, shapes, and locations to train the deep learning model effectively. This approach enabled the algorithm to distinguish between defective and defect-free components with high accuracy.

Upon testing the algorithm on physical parts, including both defective and defect-free components, the results were highly promising. The deep learning model successfully identified numerous defects in real physical parts that were previously unseen by the computer. This breakthrough technology provides a solution to one of the most challenging aspects of additive manufacturing – detecting hidden defects accurately and efficiently.

The research published in the Journal of Intelligent Manufacturing involved utilizing X-ray computed tomography to inspect the interior of 3D components with hidden features and defects. While additive manufacturing allows for the creation of complex three-dimensional components, inspecting them for defects becomes challenging when crucial features are concealed from view. The use of X-ray computed tomography proved to be a valuable tool in revealing hidden defects in additively manufactured parts.

The research team behind this pioneering technology includes experts from various institutions such as the University of Illinois Urbana-Champaign, University of Maryland, University of Michigan, and Zhejiang University. The collaboration of researchers with diverse expertise has contributed to the development of an advanced method for detecting and classifying defects in additively manufactured components.

The breakthrough in identifying defects in additively manufactured components through deep machine learning and X-ray computed tomography represents a significant advancement in the field of additive manufacturing. This innovative technology has the potential to revolutionize quality control processes in factories, ensuring that components are free of defects and meet the highest standards of production.

Leave a Reply