As the world grapples with the urgent need for sustainability, various industries are beginning to scrutinize their material choices and production processes. One sector that faces particularly intense scrutiny is battery technology, essential for enabling the shift towards electric vehicles and renewable energy systems. A recent groundbreaking study published in the Chemical Engineering Journal highlights a significant advancement in this area: the development of a fluorine-free binder and electrolyte aimed at enhancing both environmental sustainability and battery performance.

Traditional lithium batteries rely heavily on fluorinated compounds like polyvinylidene fluoride (PVDF) and lithium hexafluorophosphate (LiPF6) to function effectively. While these materials serve their purpose, they have considerable downsides. Notably, the breakdown of these compounds releases hydrogen fluoride (HF), a substance that is not only highly toxic but also detrimental to the battery’s overall performance and longevity. Furthermore, the non-biodegradable nature of PVDF presents significant environmental challenges, especially with the European Union’s tightening regulations on per- and polyfluoroalkyl substances (PFAS). These developments indicate a pressing need for alternatives that minimize ecological harm while maintaining high-performance standards.

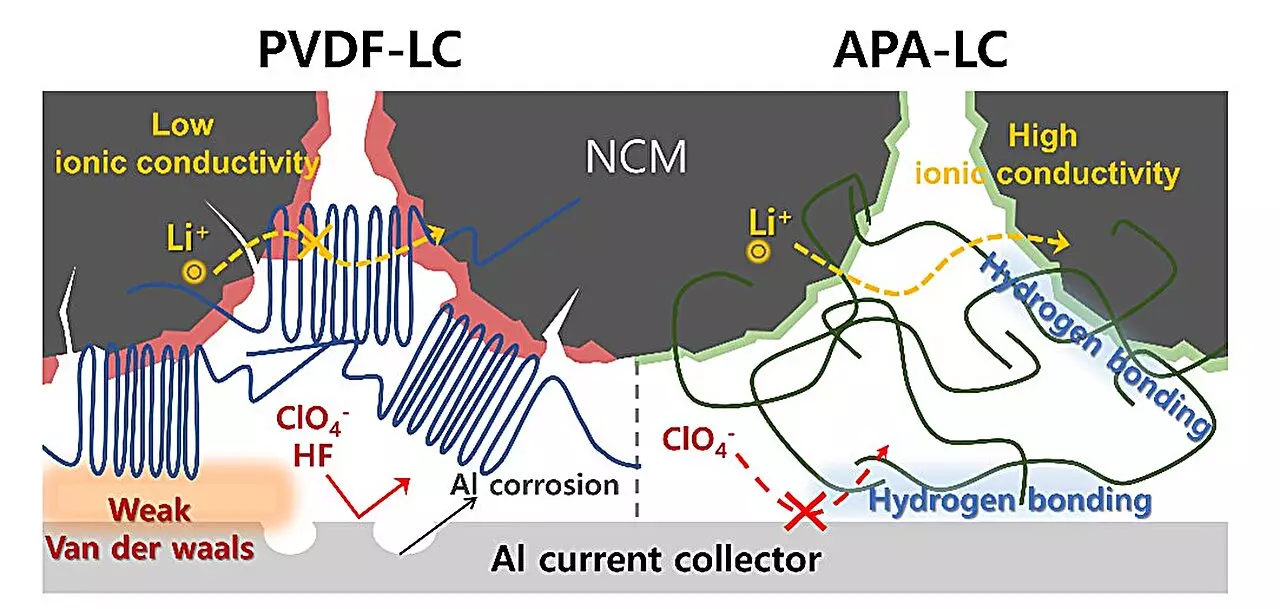

In response to these challenges, a collaborative research team from POSTECH and Hansol Chemical has introduced a revolutionary “APA-LC” system. This novel battery technology replaces fluorinated components with a lithium perchlorate (LiClO4) electrolyte and a non-fluorinated aromatic polyamide (APA) binder, both of which utilize Hansol Chemical’s proprietary technology. This significant shift marks a pivotal moment in battery design, as the “APA-LC” system is entirely devoid of fluorinated substances.

The APA binder fosters a robust connection between the cathode’s active materials and the aluminum current collector, thereby reducing electrode corrosion and extending battery lifespan. On the other hand, the LiClO4-based LC electrolyte—augmented with lithium chloride (LiCl) and lithium oxide (Li2O)—lowers the energy barrier, facilitating faster ion movement. This leads to superior lithium diffusion and enhanced output performance compared to conventional fluorinated electrolyte systems.

Remarkably, the APA-LC system demonstrates enhanced stability and performance metrics compared to existing technologies. In rigorous testing, it achieved a 20% increase in capacity retention after 200 charge cycles at a rapid 1C discharge rate, spanning a voltage range of 2.8 to 4.3 V. The team even engineered a high-capacity 1.5 Ah pouch cell, which maintained excellent discharge capabilities and showcased impressive performance under fast-charging conditions.

Professor Soojin Park of POSTECH emphasized the significance of their findings by stating, “We haven’t just replaced fluorinated systems; we’ve proven high-capacity retention and outstanding stability.” Such advancements underscore the potential of non-fluorinated systems to contribute meaningfully to the sustainability goals of the battery industry.

Addressing PFAS regulatory concerns isn’t merely a matter of environmental compliance; it also opens up substantial market opportunities. Young-Ho Yoon, Managing Director of Hansol Chemical’s Secondary Battery Materials Business, highlighted their strategic positioning within the growing global cathode binder market, projected to reach a substantial valuation of KRW 1.7 trillion by 2026. The development of eco-friendly materials continues to be vital as industries pivot towards more sustainable practices.

The shift from traditional fluorinated compounds to non-fluorinated alternatives not only aligns with evolving regulatory frameworks but also paves the way for batteries that promise both impressive performance and reduced environmental impact. The innovative work done by POSTECH and Hansol Chemical signifies a crucial step forward in the realm of battery technology, presenting opportunities to reshape industry practices while meeting sustainability goals. As the demand for eco-friendly solutions gains momentum, this pioneering research may well set a precedent for future developments in the field, illustrating that high performance and environmental responsibility can coexist harmoniously.

Leave a Reply