The landscape of modern construction is continually evolving, with ultra-high-performance concrete (UHPC) emerging as a cornerstone in innovative building techniques. Recognized for its exceptional strength and longevity, UHPC presents unique advantages over traditional concrete mixtures. However, the complexity of its behavior under various conditions presents challenges for engineers, particularly when utilizing advanced confinement methods such as fiber-reinforced polymers (FRP). Understanding these dynamics is crucial for optimizing the application of UHPC in structural designs, thereby ensuring safety and longevity in various construction projects.

A groundbreaking study published in the journal Engineering has shed light on the compressive behavior of FRP-confined UHPC through the development of a new analysis-oriented stress-strain model. Led by researchers S.S. Zhang, J.J. Wang, Guan Lin, and X.F. Nie from Huazhong University of Science and Technology and Southern University of Science and Technology, this research targets a significant knowledge gap in current structural engineering methodologies. While traditional models have effectively addressed the stress-strain relationships for normal-strength concrete (NSC) confined by FRP, they struggle to accurately represent UHPC behavior.

The study’s authors articulated a need for a refined model to better understand how UHPC reacts to concentric compression when complemented with FRP confinement. Previous models overlooked the nuances of UHPC’s performance under such conditions, leading to inconsistencies in design and safety evaluations in real-world applications.

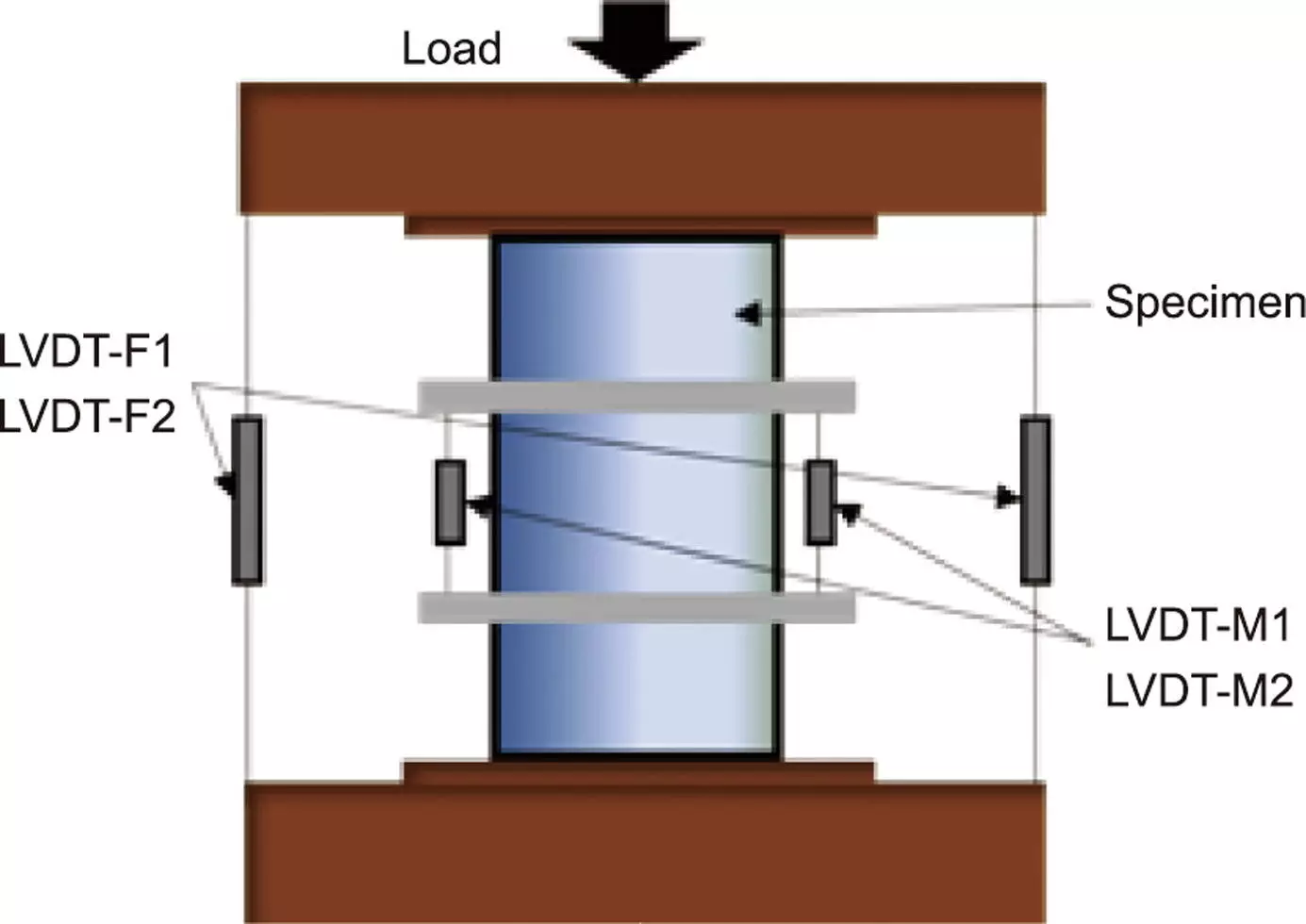

One of the key issues that emerged from the research was the inadequacy of the commonly accepted stress-path-independency assumption. This principle, which suited FRP-confined NSC effectively, failed to hold up under the distinct characteristics of UHPC. The researchers executed a series of experiments to analyze the compressive properties of UHPC with FRP confinement. They noted that the formation of diagonal cracks within the UHPC, along with the resultant non-uniform lateral expansion, diminished the effective confining pressure exerted by the FRP. This revelation underlined the complexity of UHPC’s behavior and invalidated previous assumptions that were too simplistic for these advanced materials.

To remedy these shortcomings, the authors designed an innovative model that integrates the complexities of stress-path dependency into its framework. The new model addresses the issues observed with traditional methodologies, adjusting the confining pressure dynamics and introducing an equation that tackles the confining pressure gap. This multifaceted approach allows engineers to engage with a more realistic portrayal of UHPC’s compressive behavior.

Furthermore, extensive validation using a robust database of experimental test results confirmed the model’s predictive accuracy. This rigorous analysis positions the newly developed framework as a pivotal advancement in understanding the structural behavior of FRP-confined UHPC. Enhanced predictive capability not only empowers engineers to make informed decisions but also contributes markedly to the safety and integrity of concrete structures.

The introduction of this refined model marks a significant milestone in concrete research and structural engineering. With the ability to accurately forecast the performance of FRP-confined UHPC, engineers are equipped with a powerful tool that fosters improved design strategies. This advancement opens the door to safer, more efficient UHPC applications across a multitude of structural scenarios.

Additionally, the implications extend beyond immediate design considerations; this research paves the way for future innovations in concrete technology. The newfound understanding of UHPC paves the potential for creating even higher-performance materials, thus pushing the boundaries of what is achievable within the construction sector.

As the industry moves forward, the insights from this study will be invaluable for engineers and researchers involved with UHPC. The refined analysis-oriented model offers a substantial leap forward, enabling practitioners to harness the complete potential of UHPC through proper confinement strategies. Given the ongoing evolution of construction practices, such advancements play a crucial role in shaping a resilient and sustainable future for the built environment. This blend of research and application not only enhances current structures but also fuels the drive for innovation in high-performance concrete technology, heralding a new era in construction methodologies.

Leave a Reply