At Universitat Jaume I in Castellón, a remarkable advancement in robotics has emerged from the Interactive and Robotic Systems Lab (IRS). This pioneering initiative has led to the creation of a lightweight, modular, and reconfigurable manipulator robot designed specifically for operations in hazardous settings. With a strong focus on safety and efficiency, this innovative technology can significantly reduce human exposure to dangerous environments, making it a game-changer in the field of inspection and monitoring.

The standout feature of this manipulator robot is its remote control station, which boasts advanced 3D perception capabilities. This ensures that operators can navigate and manipulate the robot effectively while receiving real-time feedback. Additionally, the IRS has integrated modular, multi-device 3D simulation software that creates a digital twin environment for enhanced operator training. This means that personnel can train extensively in a controlled, simulated setting before they engage in actual inspection tasks within hazardous locations.

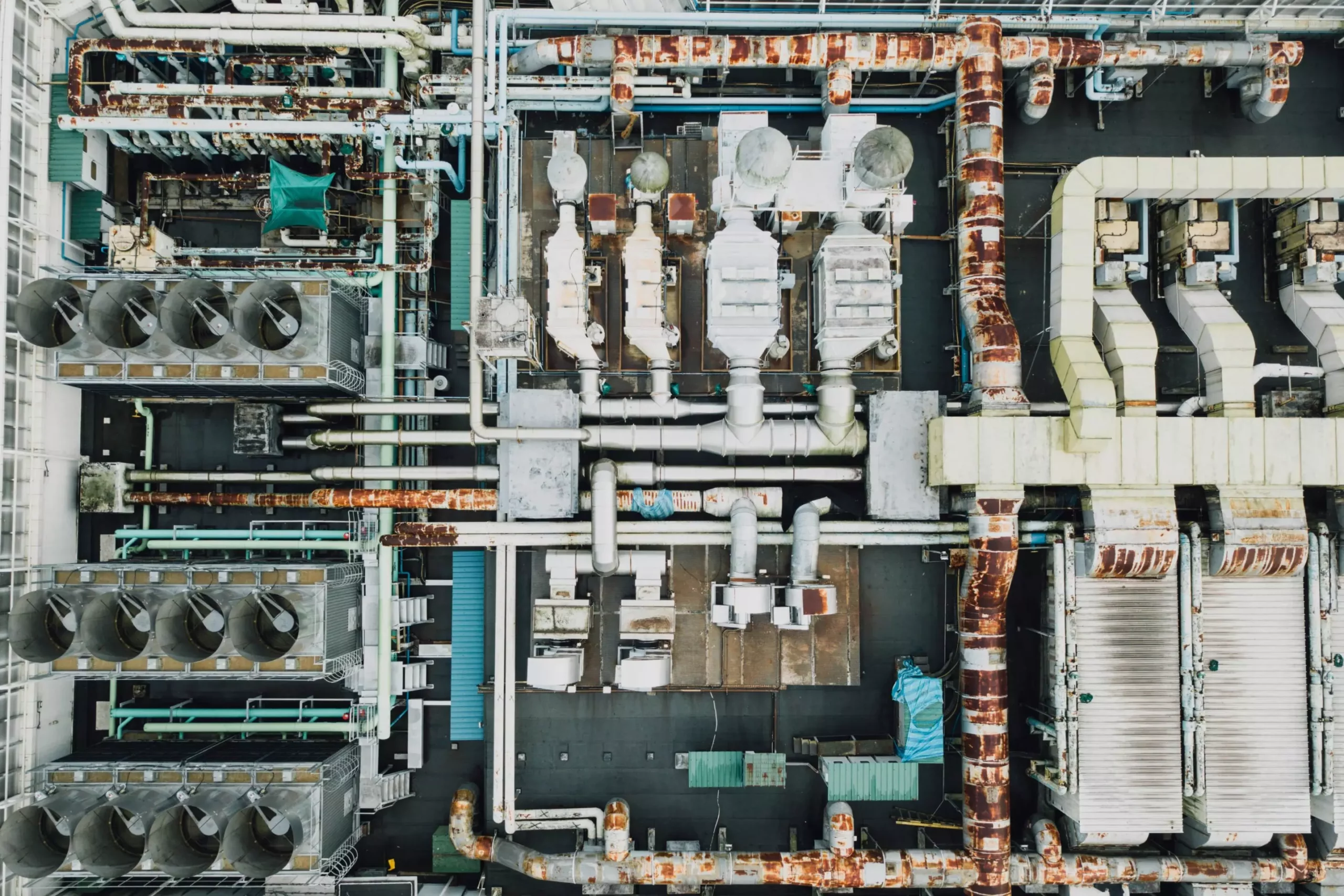

The initial focus of this technology is on inspecting plastic pipes using probing techniques and artificial vision. Not only does this enhance operational safety, but it also ensures that inspections deliver high accuracy and reliability. The hardware aspects of the robot, including wireless communication systems and various vision devices, bolster its adaptability to a variety of inspection scenarios.

The practical applications of this technology are notable, particularly in the inspection of plastic materials surrounding sensitive areas such as nuclear power plants and particle accelerators. These environments require stringent safety protocols, where human oversight can often be risky. By deploying the robotic manipulator, significant advantages in reliability and safety are achieved. Beyond industrial applications, the robot’s design allows it to be used in healthcare settings, particularly in scenarios where infectious conditions might pose risks to human workers.

The development of this manipulator robot stems from the European project “EU H2020 El-Peacetolero,” which also involves collaboration with eight other prestigious European universities and research centers. Such cooperation not only enhances the technological foundation of the project but also facilitates knowledge exchange vital for innovation.

The Universitat Jaume I acts as a cornerstone for scientific and technological advancements by providing resources through its Cooperation and Technological Development Office. By assessing industry needs and collaborating with businesses, the university ensures that its research translates into real-world applications. Motivated by the desire to disseminate scientific knowledge, UJI strengthens the bridge between research and practical implementation.

As industries continue to evolve, the integration of innovative technologies such as the manipulator robot developed by the IRS at UJI offers promising solutions to age-old challenges posed by hazardous environments. The advancements not only provide enhanced operational safety but also open avenues for training and efficiency previously thought unattainable. The continued effort to refine these technologies in collaboration with industry partners will undoubtedly lead to broader applications and improved safety protocols across diverse sectors.

Leave a Reply