As global demand for renewable energy technologies surges, driven by the urgent need to combat climate change, the recycling of rare-earth elements (REEs) becomes increasingly crucial. REEs, especially neodymium (Nd) and dysprosium (Dy), are integral to the functionality of high-performance magnets utilized in green technologies such as electric vehicles (EVs) and wind turbines. However, traditional recycling methods for these vital materials often fall short—being both energy-intensive and environmentally detrimental. Recognizing this challenge, researchers from Kyoto University have introduced a groundbreaking approach that promises to enhance the efficiency and sustainability of REE reuse.

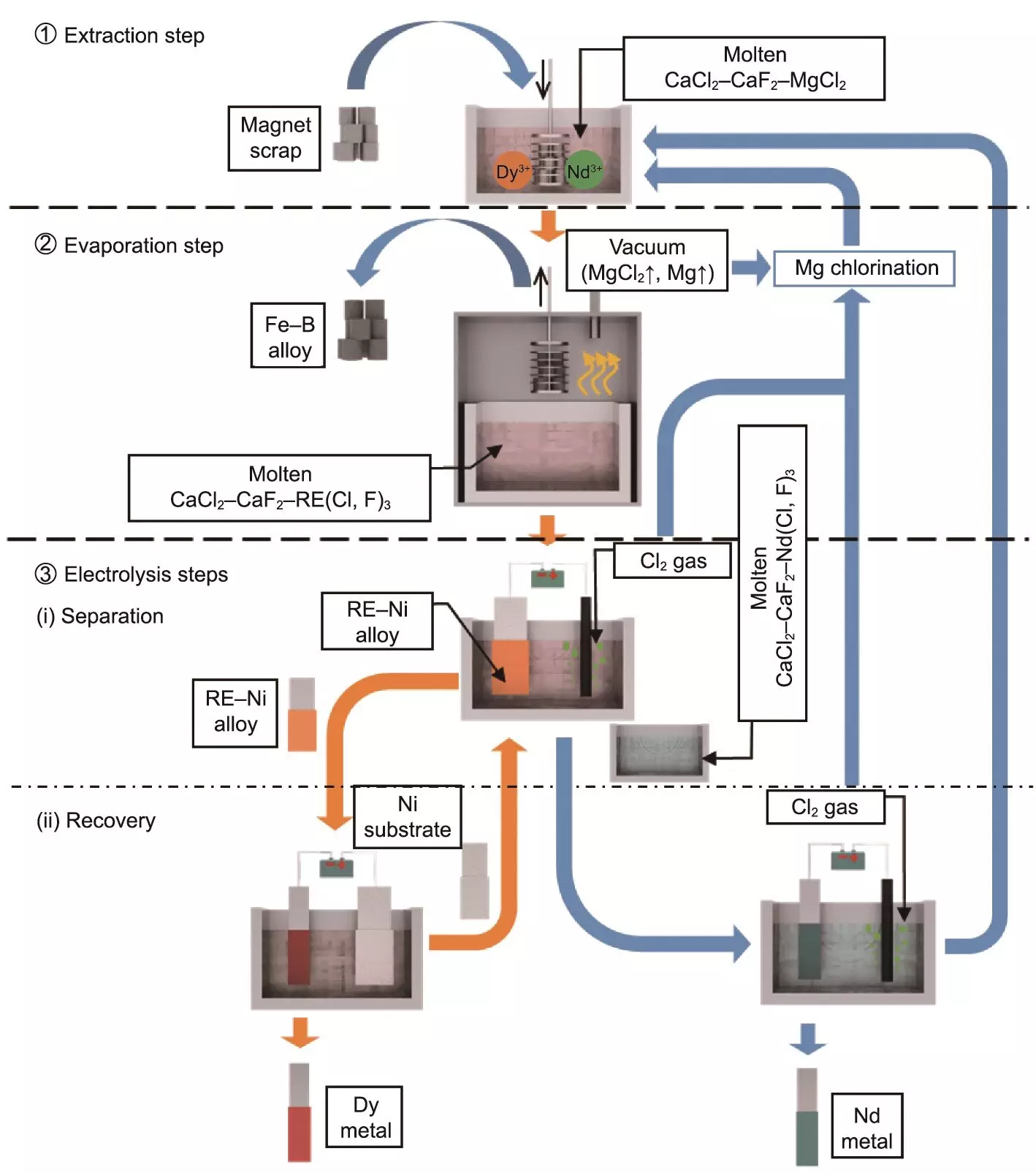

The new technique, referred to as the selective extraction–evaporation–electrolysis (SEEE) process, marks a significant evolution in the recycling landscape. Under the leadership of Professor Toshiyuki Nohira and his dedicated team at the Institute of Advanced Energy, this innovative method presents a systematic, three-phase approach. Each phase of the SEEE process is designed to optimize the extraction of REEs, thus surpassing existing methods in both performance and ecological impact.

In the initial stage of selective extraction, the team employs a molten salt mixture comprising calcium chloride (CaCl2) and magnesium chloride (MgCl2). This mixture effectively draws REEs from magnet scraps, while the incorporation of calcium fluoride (CaF2) serves to minimize evaporation losses. This meticulous effort in the extraction stage enhances the overall efficiency of the process, setting a robust foundation for the subsequent phases.

The second phase—selective evaporation—focuses on eliminating any residual extraction agents and byproducts. This step is essential in concentrating the REEs, making the following electrolysis both straightforward and effective. Finally, during the selective electrolysis stage, the researchers utilize the varying electrochemical properties of the REEs to separate them based on their formation potentials. This intricately designed stage ensures the recovery of high-purity neodymium and dysprosium metals.

The results stemming from this pioneering study are noteworthy: the SEEE process achieved recovery efficiencies of 96% for neodymium and 91% for dysprosium, with purity levels exceeding 90%. Such impressive outcomes signal a paradigm shift in REE recycling, presenting a sustainable alternative to conventional methods fraught with complexities and excessive resource consumption.

Moreover, the environmental implications of the SEEE process cannot be overstated. As the global market for EVs and renewable energy technologies continues to expand, the demand for efficient recycling solutions for REEs grows sharper. The SEEE process emerges as a viable response to these demands, potentially mitigating the ecological costs associated with mining operations, which can be devastating to local environments.

While this innovative process has been tailored specifically for recycling neodymium magnets, the researchers believe its applications may extend to other domains, including the reprocessing of nuclear fuels. This versatility could further amplify its relevance across various industrial sectors, marking a significant step toward comprehensive resource management.

However, despite the promising results, the researchers emphasize the necessity for continued technical investigations to facilitate the full integration of the SEEE process into industrial frameworks. Future studies will be crucial in addressing the technical challenges that may arise with scaling up and ensuring that this method can be widely adopted across the recycling industry.

The advancements presented by the SEEE process underscore a vital intersection between technological innovation and environmental stewardship. As we navigate an era where the urgency for sustainable practices is paramount, breakthroughs like this one highlight the role of advanced research in shaping a carbon-neutral future.

By fostering solutions that are not only effective in resource recovery but also respectful of ecological integrity, the SEEE process stands as a pivotal development in the ongoing quest to reconcile technological progress with sustainability. As more researchers and institutions engage in similar pursuits, the journey toward a more sustainable world becomes not just possible but inevitable.

Leave a Reply