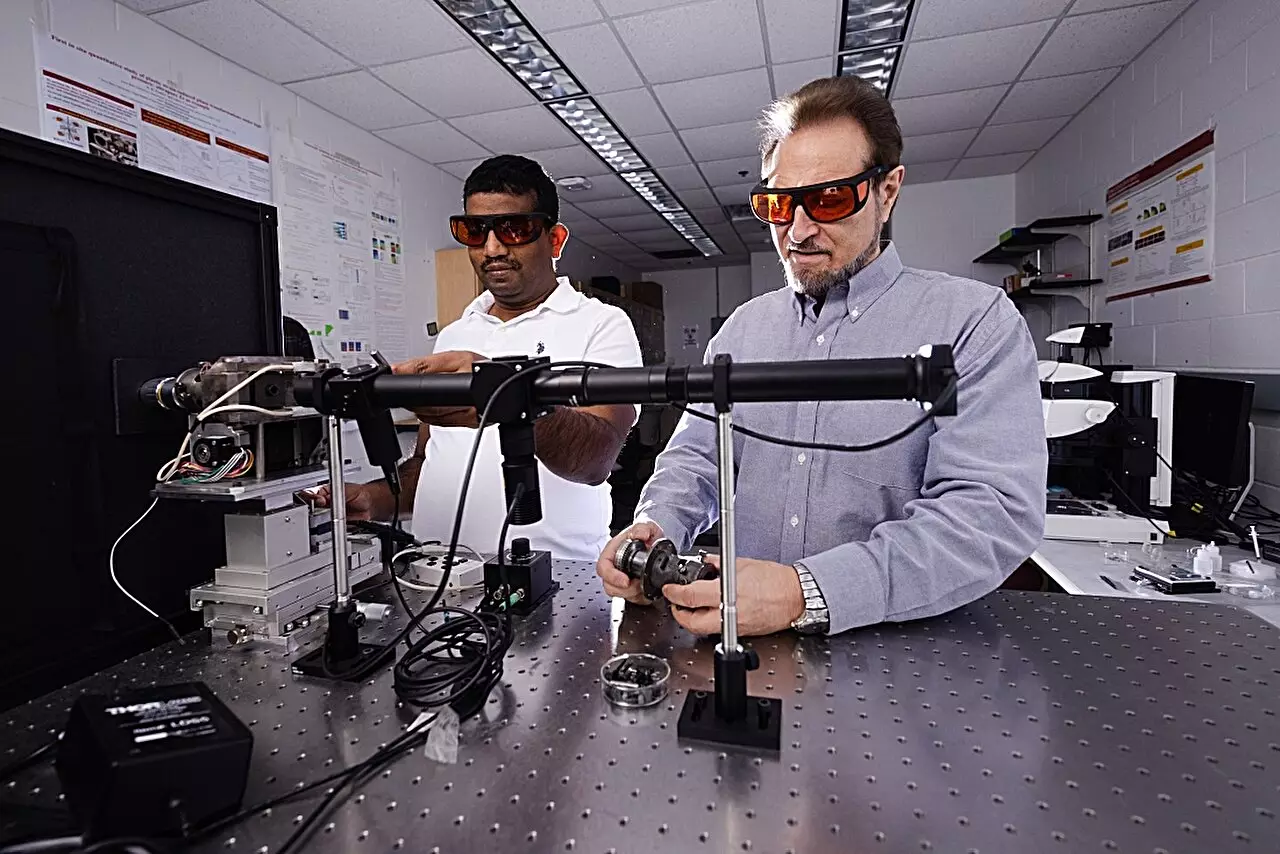

In 1999, Valery Levitas embarked on an ambitious journey, moving from Europe to the United States equipped with a groundbreaking tool—the rotational diamond anvil cell. This device, sophisticated in its ability to apply pressure and shear to materials, has enabled Levitas and his team at Iowa State University to delve into the complexities of material science. What distinguishes their research is the exploration of material behavior under real-time conditions, allowing them to observe and verify theoretical predictions regarding phase transitions and structural changes in materials.

This intersection of disciplines—mechanics, physics, material science, and applied mathematics—creates a rich tapestry of inquiry that continuously evolves. It invites questions: How do materials like silicon respond under extremities? Do these alterations give birth to new properties beneficial for technological advancements? The methodological sophistication of their experiments has propelled Levitas’s work into the spotlight of modern engineering research.

Silicon’s status as a cornerstone of the electronics industry makes its study particularly vital. Recent findings published in *Nature Communications* by Levitas and his collaborators shed light on silicon’s phase transformations under simultaneous pressure and plastic shear deformation. This innovative approach diverges from traditional studies that typically investigate silicon under high pressure alone.

The research employed a unique method of compressing silicon in three distinct particle sizes—1 millionth of a meter, 30 billionths of a meter, and 100 billionths of a meter—to ascertain how these variations affected performance under extreme conditions. It became evident that subjecting silicon to plastic strain-induced phase transformations led to distinct and previously undocumented phenomena. This experimental advantage underscores the critical need for understanding nanoscale materials in a practical, scientific context.

Levitas and his team’s investigation revealed that silicon undergoes a significant transformation from its “Si-I” phase to the “Si-II” phase at a mere 0.3 gigapascals when subjected to room-temperature environments and accompanied by plastic deformation. This stands in stark contrast to the known pressure threshold of 16.2 gigapascals necessary for transformation through pressure alone. The stark reduction of transformation pressure by a factor of 54 is a breakthrough that challenges long-standing theories in materials science.

This research offers promising implications for industrial applications. Levitas emphasizes that traditional methods requiring high pressure are often impractical for widespread industrial use. However, by employing plastic deformations, transformations that once necessitated extreme conditions can now be accessed at manageable pressures, thereby opening doors to new manufacturing processes and material functionalities.

At the heart of Levitas’s research is the quest to alter microstructures rather than merely modifying the shape or size of material samples. He posits that the transformation of silicon’s microstructure results in various crystalline phases, each with unique properties that can be harnessed for practical applications. The research identifies seven different phases of silicon, each characterized by a distinct lattice structure, linking these transformations to varying electronic, optical, and mechanical properties.

The potential for creating nanostructured materials or composite mixtures with optimal traits is tantalizing for industries seeking advancements in material performance. The versatility and multitude of possible applications signal a promising frontier for technological development across sectors reliant on silicon.

Levitas’s two-decade journey into the realm of materials research culminates in a profound understanding of silicon’s behavior under unusual conditions—a result he anticipated based on his theoretical framework. His assertion underscores the importance of rigorous theoretical predictions in guiding experimental exploration. This synthesis of thought and experiment not only enriches the academic discourse but also fuels innovation that can eventually transform numerous industrial practices.

The work conducted by Levitas and his colleagues epitomizes a pioneering spirit in material science. The implications of their findings extend beyond academic inquiry, foreshadowing a shift in how industries might approach the design and application of electronic materials in the future. Embracing the challenges and possibilities presented by advancements in compression techniques, researchers stand on the brink of exciting innovations yet to be realized.

Leave a Reply