As we stand on the cusp of a technological renaissance, the announcements from Boston Dynamics regarding its Atlas robot herald exciting developments in the realm of manufacturing. The advancement from hydraulic to electric in the Atlas model symbolizes a significant leap in robotic capabilities. Scheduled to begin operations in a Hyundai factory later this year, Atlas aims to redefine the labor force and demonstrate the potential of humanoid robots in commercial settings. This foray into production marks an evolution not just for Boston Dynamics but for industries that have long relied on traditional automation methods.

The anticipation surrounding Atlas underscores a pivotal shift in how industries perceive robotic solutions. Unlike prior iterations of factory automation that were often designed for specific, repetitive tasks, Atlas and its contemporaries are engineered for versatility. The capacity to manage heavy loads and navigate unpredictable environments positions these robots as potential partners to human workers, enhancing efficiency in ways previously thought impossible. Kerri Neelon, spokesperson for Boston Dynamics, aptly describes the robot’s capabilities as bridging a gap that has long challenged human labor—lifting awkward objects or tackling physically demanding tasks.

Humanoid Robots: Not Just a Fad

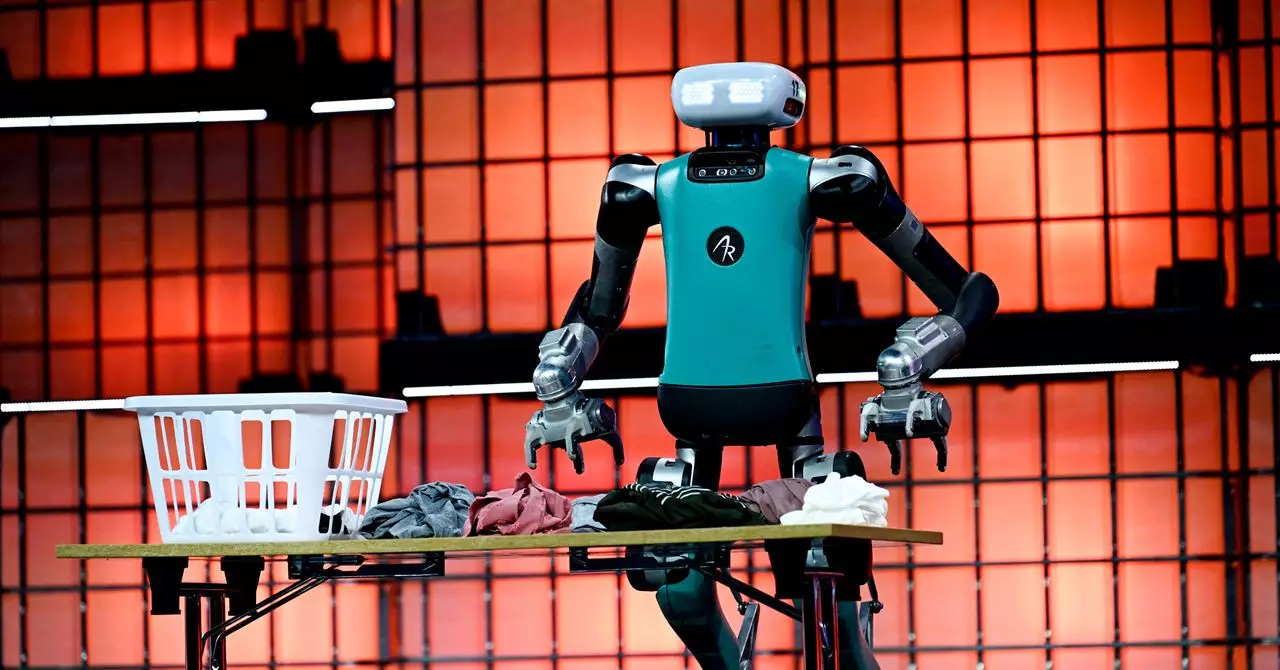

Critics might dismiss humanoid robots as futuristic novelties, conjured up straight from science fiction. However, recent developments suggest otherwise. The market appears to be on the brink of embracing humanoid robots with open arms, as evidenced by emerging players like Agility Robotics and Figure, who are already integrating their creations into warehouses and other commercial avenues. Furthermore, tech giants like Apple and Meta are purportedly venturing into humanoid robotics, hinting at a broader commitment within industries to explore this frontier.

According to a Goldman Sachs report, humanoid robots may burgeon into a substantial market, growing to $38 billion by 2035—a staggering figure that reflects a surge in both interest and investment in robotics technology. This financial projection illustrates not just an optimistic outlook, but a confirmation that humanoid robots could fulfill essential roles in diverse environments, allowing for adaptability comparable to human workers. This comparison presents a fundamental shift from the one-dimensionality of traditional assembly lines toward a more dynamic workforce that can tackle multiple tasks.

Challenges and Concerns: The Path to Integration

Yet, the journey to fully integrating humanoid robots into the workforce is not without its hurdles. Despite the excitement around products like Tesla’s Optimus, concerns loom regarding the capabilities of these robots in autonomous function. Initial demonstrations indicated that human control was still a requisite, a revelation that has sparked skepticism regarding the autonomy and reliability of these systems. In an industry where expectations are continually rising, any misstep can lead to serious doubts about profitability and efficacy.

The issue is compounded by supply chain challenges that affect the availability of critical components. Elon Musk’s mention of production hurdles due to rare-earth metal export restrictions from China emphasizes the fragility of the technological landscape. This reality raises questions about whether our dreams of a seamless transition to humanoid robotic labor are feasible or just aspirational fantasies tethered by real-world constraints.

A Harmonious Workforce: Robots and Humans Side by Side

What remains clear, amidst both enthusiasm and skepticism, is the necessity for a balanced coexistence between human workers and robots. Jonathan Hurst, cofounder of Agility Robotics, articulates an important perspective in which humanoid robots augment human labor instead of fully replacing it. By engaging in tasks requiring flexibility and adaptability, these robots can coexist with existing workforce models, opening doors to new workflows that optimize human capabilities.

In a world designed for human activities, Boston Dynamics’ Neelon asserts that robots should reflect human needs and values. When designed thoughtfully, humanoid robots can facilitate safer workplaces and extend human capacities. This idea champions a future where labor demand can be met sustainably while empowering workers to focus on creative and complex challenges that defy mechanical replication.

Overall, as we grapple with the implications of humanoid robots, it is essential to view them as allies rather than adversaries in the ascent of a new industrial era—one that embraces the rich potential of human-robot collaboration.

Leave a Reply