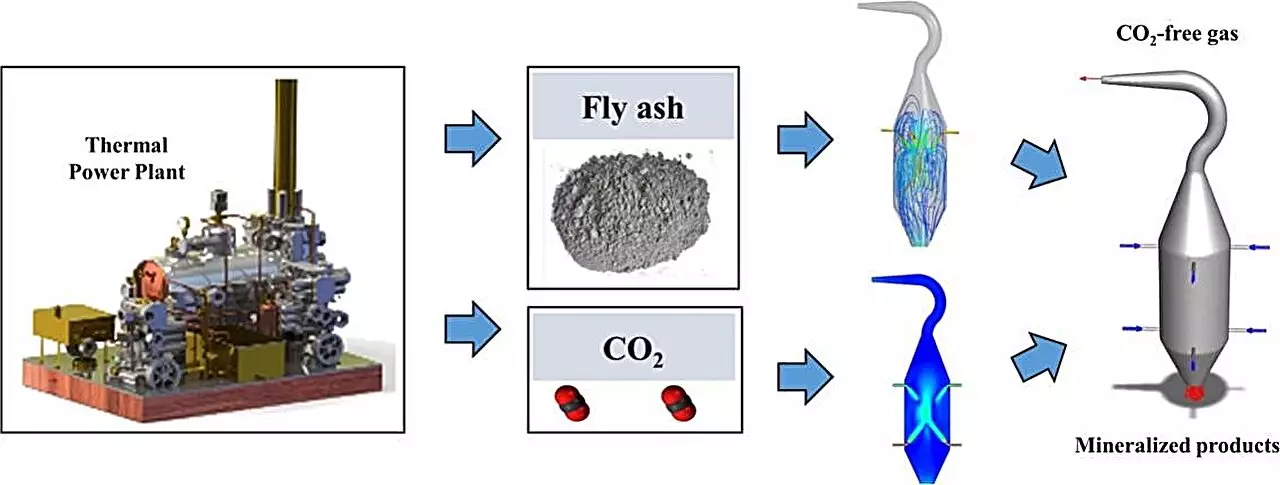

The quest for sustainable waste management and CO2 sequestration has led researchers to develop innovative reactors that mineralize carbon dioxide using fly ash particles. This cutting-edge technique not only provides a long-term solution to the pressing issue of greenhouse gas emissions but also repurposes an industrial by-product in the process.

The increase in CO2 emissions due to industrialization has become a significant driver of global warming. While current carbon capture, utilization, and storage (CCUS) technologies exist, they struggle with efficiency and cost concerns. Fly ash, a by-product of coal combustion, presents a promising avenue for CO2 mineralization, effectively transforming waste into a valuable resource that can help mitigate emissions.

The challenges faced by existing reactor designs highlight the importance of exploring new configurations and operational fine-tuning. Research conducted by Shanghai Jiao Tong University on fly ash mineralization reactors introduces groundbreaking designs that aim to enhance CO2 capture and mineralization efficiency. By utilizing computational fluid dynamics, the study identified two distinct reactor designs tailored for CO2 mineralization using fly ash.

One of the reactor designs features an impinging-type inlet design that maximizes gas-particle interactions, leading to extended particle dwell times and increased mineralization rates. On the other hand, the quadrilateral rotary-style inlet design prioritizes streamlined flow for optimal mixing and reaction efficacy. Through a detailed analysis of operational parameters such as flue gas velocity, carrier gas velocity, and particle velocity, the study identified optimal ranges that promise to elevate reactor performance and ensure efficient CO2 mineralization.

Dr. Liwei Wang, the principal investigator of the study, emphasized the significance of their findings in advancing carbon capture and utilization technologies. By refining reactor designs and operational parameters, the research team achieved a substantial improvement in CO2 mineralization efficiency. This development not only benefits sustainable waste management but also provides a practical strategy for reducing industrial carbon emissions, aligning with global climate action initiatives.

Transformative Impact

The implications of this research extend to coal-fired power plants, offering a novel approach to the utilization of fly ash generated during combustion. By redirecting this industrial by-product towards CO2 mineralization, the study opens the door to decreased carbon emissions and a reduction in the environmental impact of fly ash disposal. The wide-ranging applications of this research present a harmonious solution to waste management and CO2 sequestration, potentially reshaping the landscape of CCUS technology approaches.

The development of advanced reactor designs for CO2 mineralization using fly ash represents a significant milestone in the journey towards sustainable waste management and climate action. By leveraging innovative technologies and operational strategies, researchers are paving the way for a future where carbon capture and utilization are integral components of a low-carbon economy.

Leave a Reply