In the ever-evolving landscape of energy storage, sodium-ion batteries have emerged as a promising alternative to the widely used lithium-ion batteries. These next-generation secondary batteries utilize sodium, an element that is not only more abundant but also easier to extract than lithium, the primary component of current battery technologies. Sodium, found in everyday salt, has the potential to significantly alter the economics of battery production while enhancing safety and operational stability. Researchers have been diligently exploring this innovative avenue, driven by the need for more efficient and environmentally friendly energy storage solutions.

Despite their advantages, sodium-ion batteries contend with several inherent challenges. Chief among these is their lower energy density compared to lithium-ion counterparts, which limits their overall usability in energy-intensive applications. Additionally, the manufacturing processes associated with sodium-ion battery components, particularly the anodes, are complex and cumbersome. Sodium ions are larger than lithium ions, necessitating the use of hard carbon materials, which have special structural properties that allow them to accommodate such size differences. The creation of this hard carbon is not a straightforward task; it requires a precise carbonization process — one that is energy-inefficient and costly. These obstacles have hindered the realistic commercialization of sodium-ion batteries, despite their vast potential.

Innovative Solutions: Microwave Induction Heating

A team of researchers from the Korea Electrotechnology Research Institute (KERI) may have cracked the code to overcoming some of these barriers. Led by Dr. Daeho Kim and Dr. Jong Hwan Park, the team has developed an ultrafast preparation method for hard carbon anodes that utilizes microwave induction heating. This novel process can create hard carbon anodes in just 30 seconds — a significant improvement over traditional techniques, which often require hours at high temperatures.

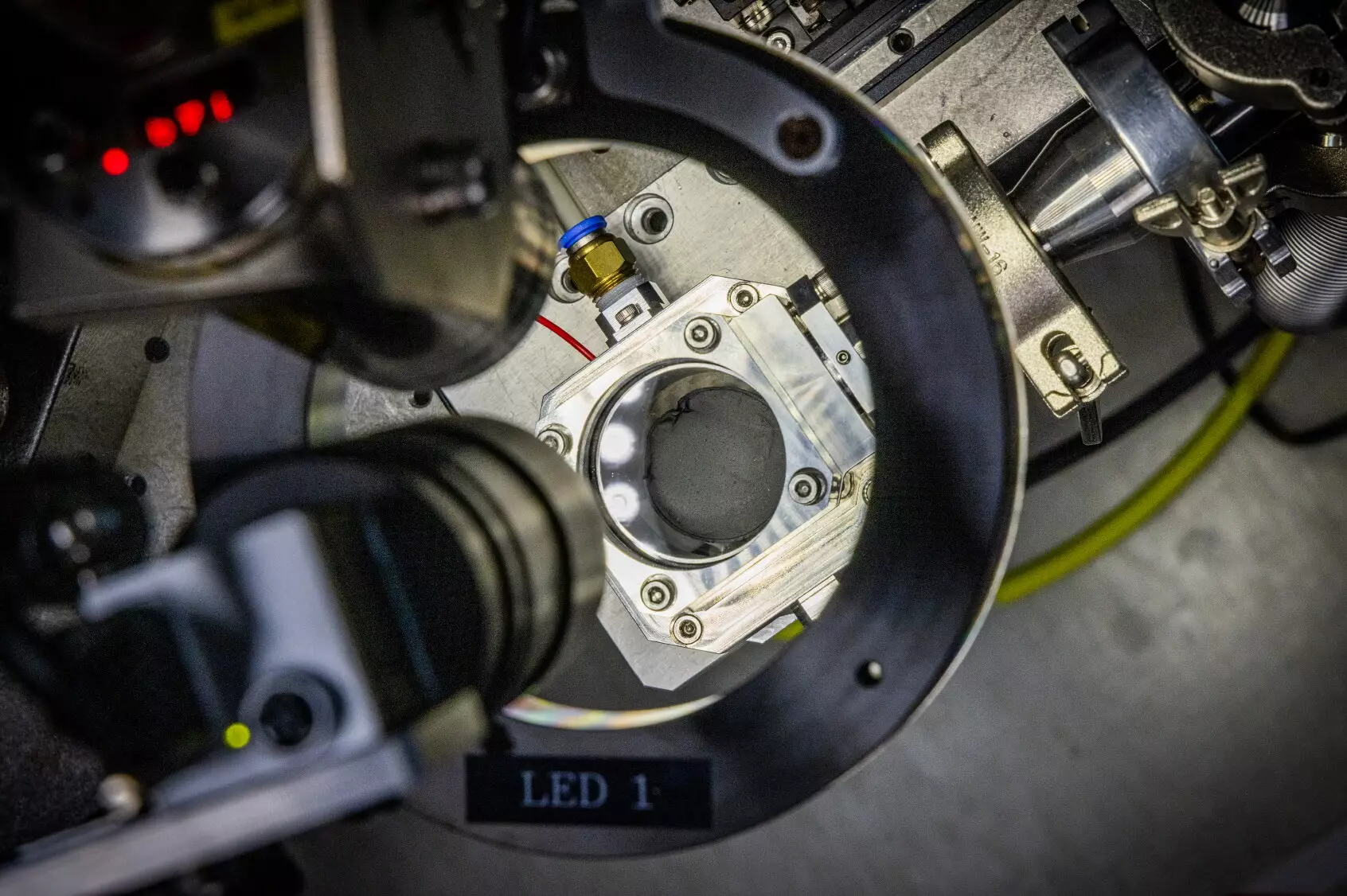

The methodology involves mixing polymers with carbon nanotubes to create thin films, which are then exposed to a microwave magnetic field. By inducing electrical currents in the carbon nanotubes, the films can be rapidly heated to over 1,400 degrees Celsius. This pioneering approach not only reduces the time and energy costs associated with the carbonization process but also enhances the overall feasibility of producing sodium-ion batteries on a larger scale.

One of the pivotal elements of this research is the multiphysics simulation technique employed by the team. This advanced methodology provided critical insights into the electromagnetic interactions within the microwaves applied to nanomaterials. Such an understanding has allowed for the optimization of the hard carbon preparation process, paving the way for more efficient battery production. The implications of this research are profound, especially given the growing demand for energy storage solutions that are both effective and safe for consumers.

In light of recent concerns surrounding the safety of lithium-ion batteries, particularly in electric vehicles where incidents of fires have been reported, the interest in sodium-ion batteries is likely to surge. Their inherent electrochemical stability makes them particularly well-suited for applications in diverse environments, including extreme cold conditions, further increasing their market appeal.

Commercialization and Broader Applications

As the team at KERI moves forward, their aspirations extend beyond merely enhancing the performance of their sodium-ion battery anodes. They aim to establish technologies capable of mass production for large-area hard carbon films, ensuring that their innovative processes can meet growing market demands. The potential applications of their microwave induction heating technology also promise to transcend the realm of sodium-ion batteries; there are prospects for its utility in smaller, high-temperature production processes, such as those required for all-solid-state batteries.

KERI’s proactive approach in securing a domestic patent reflects their commitment to transforming this technology into a commercially viable solution. Early indications suggest that there will be considerable interest from industry stakeholders involved in energy storage materials, laying the groundwork for future technology transfer agreements.

The advancements made by Dr. Kim, Dr. Park, and their team represent a significant leap forward in the realm of battery technology. The convergence of increased safety, economic feasibility, and efficiency encapsulated in sodium-ion battery production through microwave technology positions this innovation as a frontrunner in the future of energy storage. As research continues to evolve and industry partnerships form, we may be on the brink of a new era where sodium-ion batteries play a central role in powering our devices, vehicles, and ultimately, our sustainable future.

Leave a Reply