The construction sector is currently facing numerous challenges that are impacting the environment and the industry as a whole. One significant issue is the depletion of natural sand, which is predicted to be scarce by 2050. Additionally, carbon dioxide emissions, particularly from the production of cement and fired clay bricks, are on the rise. Furthermore, there is a substantial amount of construction and demolition (C&D) waste being generated annually, with a low recycling rate of only about 1% in India.

Researchers at the Center for Sustainable Technologies (CST) at the Indian Institute of Science (IISc) are tackling these challenges by exploring innovative solutions. One approach they are investigating is the storage of carbon dioxide from industrial flue gas in excavated soil and C&D waste. By utilizing these materials, there is potential to partially replace natural sand, reducing the environmental impact of construction materials while enhancing their properties for construction applications.

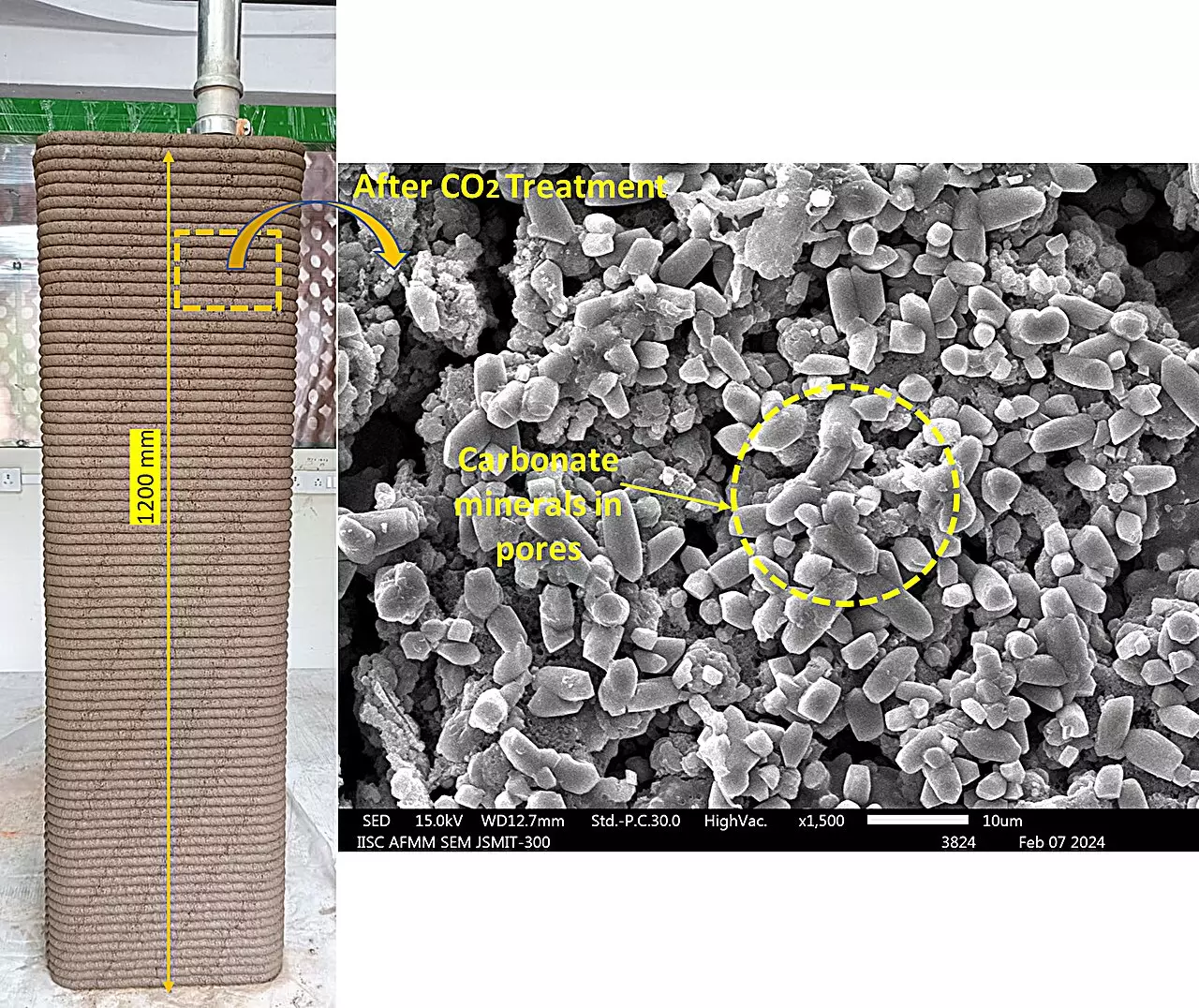

Studies conducted by the CST team have demonstrated promising results. By replacing natural sand with carbon dioxide-treated C&D waste in mortar and curing it in a CO2-rich environment, there was a significant improvement in the material’s engineering properties. This process led to an increase in compressive strength by 20-22%, showcasing the potential for sustainable construction materials.

Innovative approaches such as injecting carbon dioxide gas into clayey soil have shown benefits in stabilizing clay, reducing surface area and pore volume, and improving the overall engineering performance of the material. Additionally, the development of 3D-printable materials using excavated soil combined with binders like Portland cement, blast furnace slag, and fly ash has shown potential in reducing the need for cement and natural sand in mortar production.

Moving forward, the CST team plans to further investigate the impact of industrial and simulated flue gas on the properties of newly formulated materials. Understanding how different gases affect the materials’ carbon-capturing potential and engineering properties will be crucial for their application in the construction industry. The team is also in discussions with major construction companies to implement these sustainable materials in their manufacturing processes.

The future of sustainable construction materials lies in innovative solutions that address the environmental challenges faced by the industry. By utilizing carbon dioxide-treated materials, such as excavated soil and C&D waste, there is an opportunity to create low-carbon prefabricated building products that align with decarbonization targets. The research conducted by the CST team is paving the way for a more sustainable and environmentally friendly approach to construction materials, ultimately contributing to the fight against climate change.

Leave a Reply